Pressure Decay Leak Testing

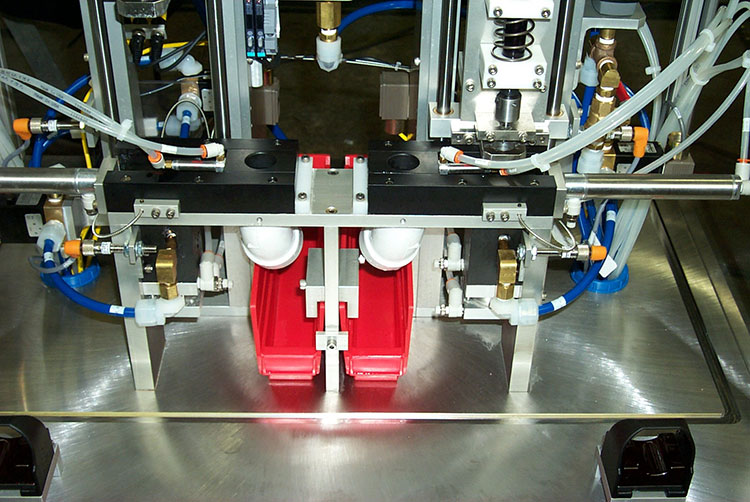

Our pressure decay leak testing method starts with automatically filling the product to the customer’s specified pressure (test can range from 5 to 1200 PSI), isolate, stabilize, perform the leak test and measure the decay for the duration of the required customer leak testing time. Our equipment can seal multiple orifices and bores with expanding seals, flat seals, o-ring seals and custom curved seals.

Dunk Leak Testing

Dunk leak testing may be used when a product has failed a typical pressure leak test although no leak can be seen. First, water is filled into a stainless-steel vat. Then the product is loaded into a custom fixture and then automatically sealed, pressurized and submerged into the water. The operator visually inspects the product for air bubbles to determine the location of the leak, and then the operator marks the product to indicate the leak location. This test is helpful to diagnose upstream manufacturing errors.